Week 14: Optimizing a 50-employee business using AI Pt 2: Job Activity Optimization

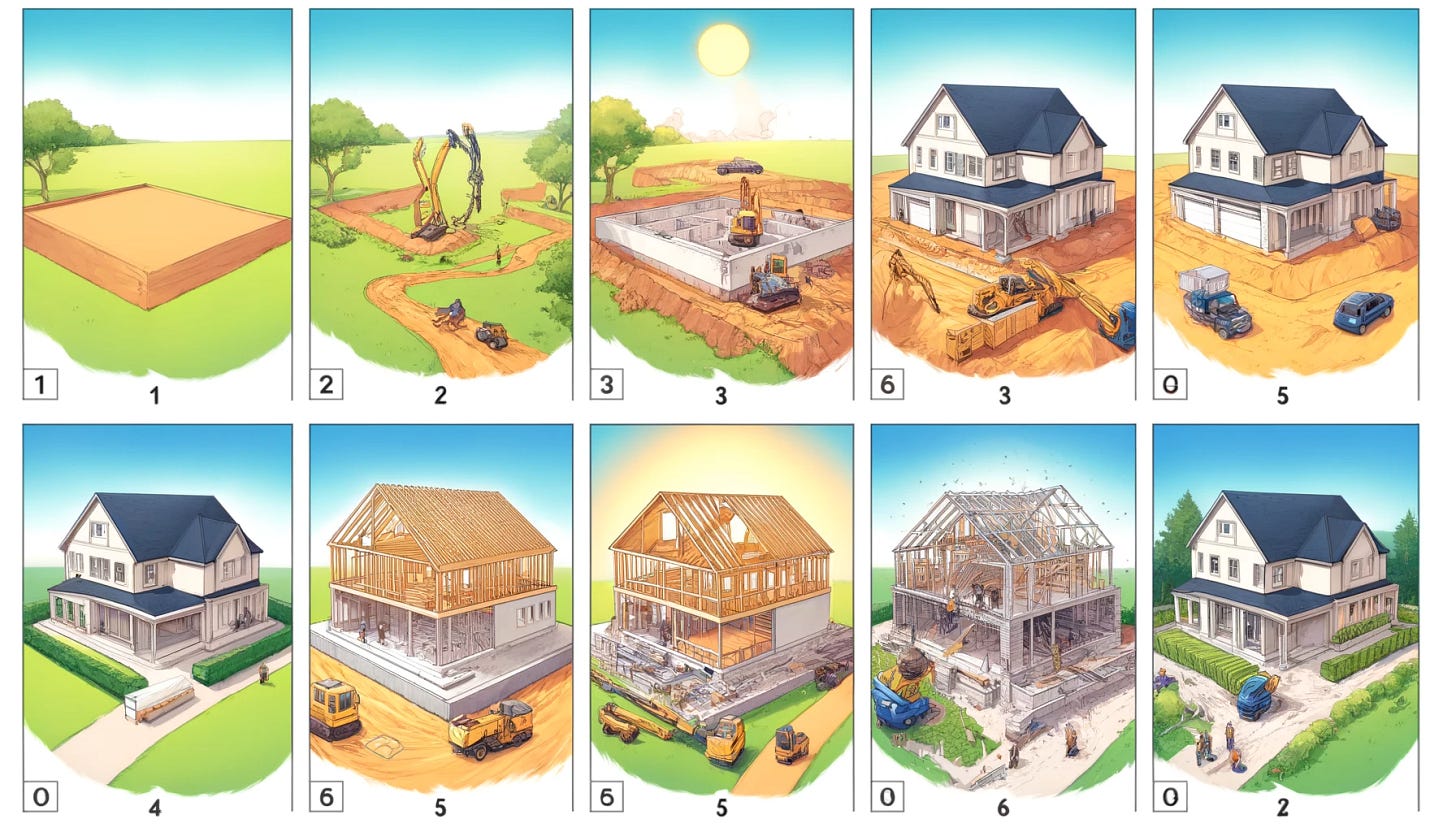

Process, assembly and test

This week, we delved deeper into the individual activities our employees do to find a better way to organize our system.

This edition has the following sections:

Learning: Video on our permitting chain

Adding Value: Job Activity Optimization

Interesting things: Tweets

Enjoy!

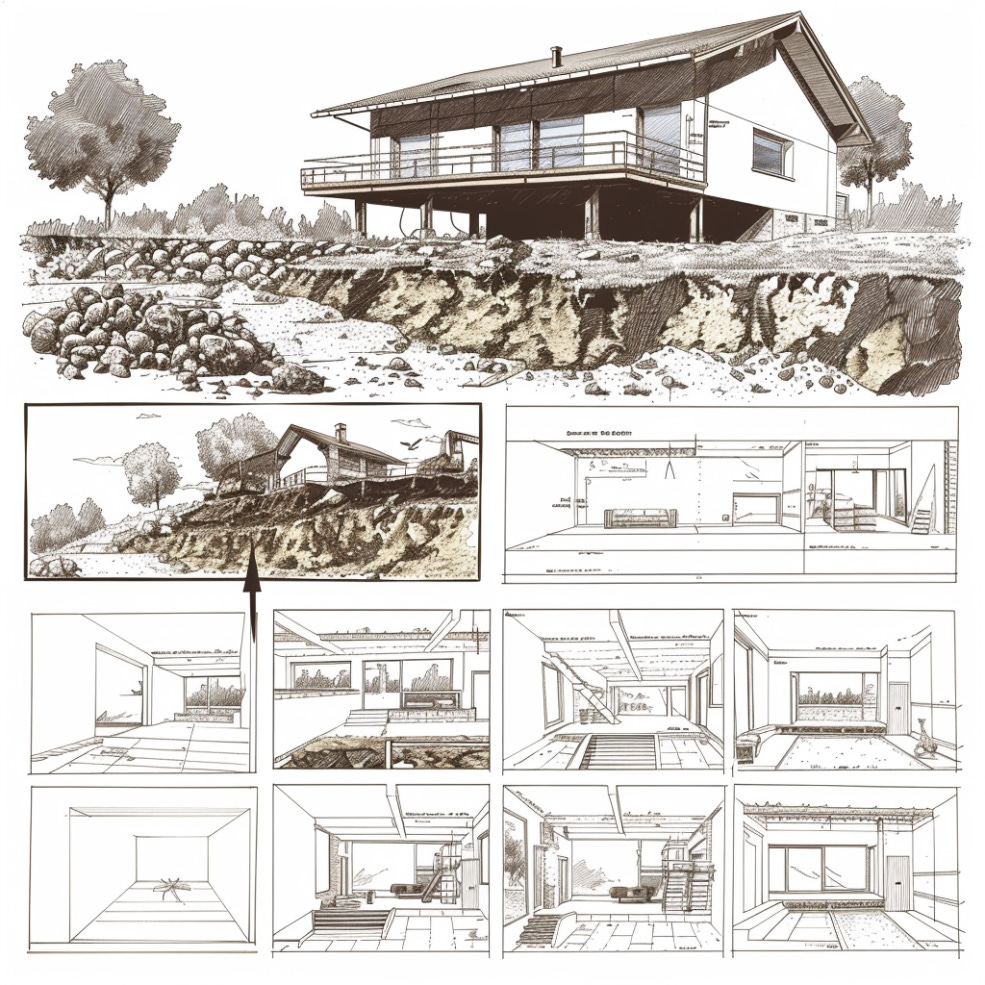

Learning: Sneak Peek at Our Permitting Breakdown

Here is a link to the video that also has closed captioning and more features to make your watching more enjoyable

Adding Value: Job Activity Optimization

This week, I sat down again with the team, planning to dissect each department and look at the activities that make up each job in each department.

We are taking a page out of Andy Grove’s high-output management to categorize each job activity as a process, assembly, and test where

Process

This refers to activities that involve the operation's planning and execution strategy. This includes meetings, job documentation, managing, and communication between team members. Examples of this in our operation include using our software to add daily reports on jobs or looking at trends in our job progress to decide how to move around the pieces involved, such as our contractors and material suppliers. It coordinates the project as a whole.

Gameplan

One thing we’ve done over the last six months that has been beneficial is collecting data on all of our processes through our internal software. We know precisely what assembly activities are conducted daily, how long they take, and how much they cost. The problem we will solve moving forward is having someone in charge of looking at these metrics to

1. Keep the team in check to meet our schedule deadlines. This will create accountability and ensure they are monitored for all their activities.

2. Identify trends in the data, such as where we’re spending more money or what we’re taking the most time doing.

We have a new Quality Assurance Manager starting next week who will facilitate these things.

Assembly

This is the work itself. When our contractors go out and assemble the plumbing system in the home, that is what I’m talking about. The assembly process “assembles” the actual product, a space for people to inhabit, whether a house, apartment, office, or warehouse space.

Gameplan

For our assembly activities, the most important thing is having clearly defined tangible KPIs. We need to enforce things such as construction times and quality, and we need a person who is ultimately responsible for each activity. Elon Musk has a policy that every activity must be tied to a name; if that activity fails, it means that person fails. That is what we must do here. So, for each activity, we are sitting down and figuring out, “Who is in charge of this activity?” and subsequently, “How do we know they’re doing a good job?”. This is where the KPIs come in. Again, we had done much of this before, but it was very unspoken and implied. We are now clarifying who is in charge and what we are measuring.

Test

The testing activities match up the process and the assembly. Is the job done to the specifications that we desire?

Gameplan

We realized that we needed formal tests in our job process. The testing was more of an unspoken thing that our superintendents did when they checked the job site, but we currently don’t have a systematic method for it. Furthermore, we relied on the city inspections to gauge whether we did a good job, but that is not enough. To save time and money, we must ensure the job is done correctly before the inspectors look at the work. This is one of the things we will add to all of our job processes moving forward. Someone will complete testing activities at specific critical points during construction.

One note about testing is that you want to identify mistakes at the lowest possible cost. Identifying a problem with the home's design at the beginning stage of construction, say the form, is much less costly to fix than identifying it once the masonry blocks are laid out. This is because as the project continues to move forward, it becomes more valuable than it was before. You are adding material and manpower to the equation the further you go, so for a change in design, you would have to redo more of the job or start from scratch where those resources you already expended would go to waste.

The Limiting Step

The final thing we did this week was to identify

Keep reading with a 7-day free trial

Subscribe to Adan’s Newsletter to keep reading this post and get 7 days of free access to the full post archives.